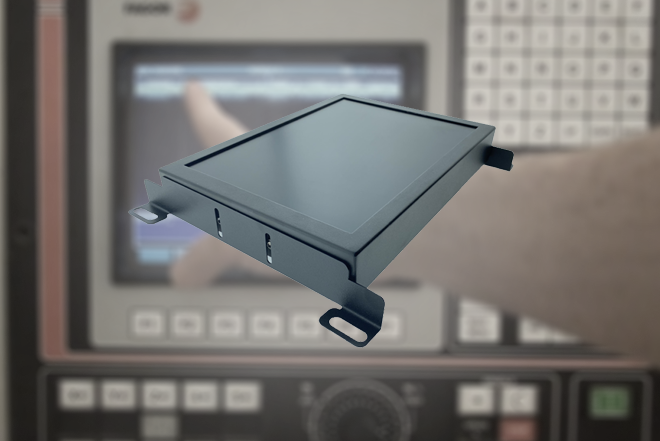

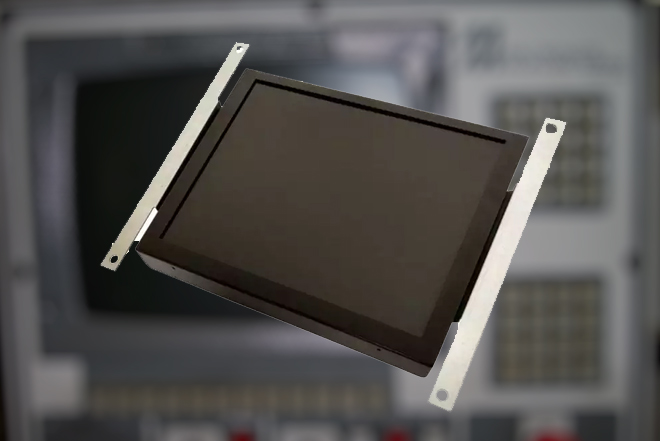

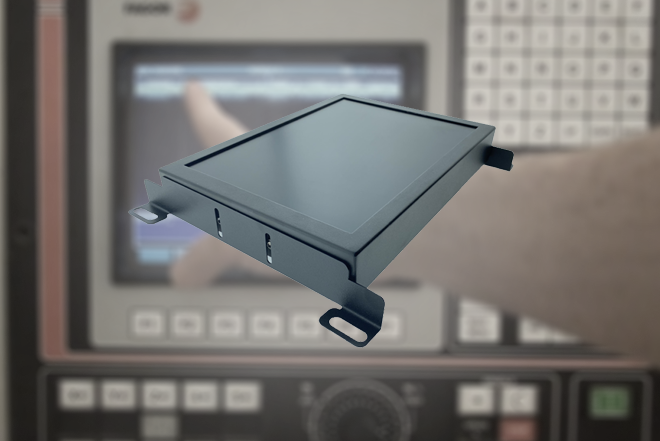

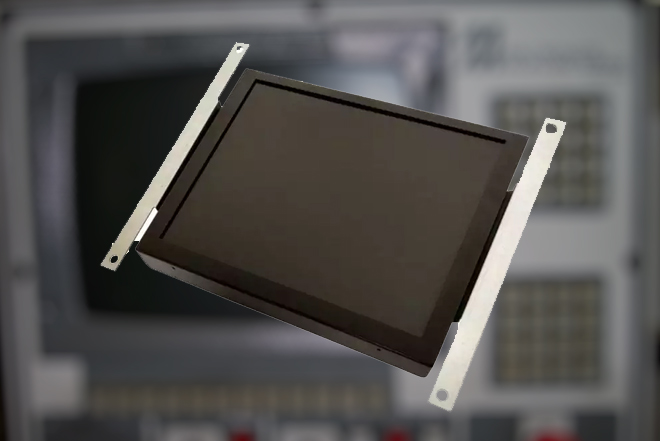

Fagor LCD Replacement: Upgrade Your Machines with Monitech Are you in need of a high-quality LCD replacement for your Fagor machine? Look no further than Monitech. With our wide range of LCD upgrade kits, we provide reliable solutions to enhance the performance and longevity of your Fagor machines. Whether you have a Fagor 8025, 8050, CNC 8030, 8050M Motion Master, 8035, or even a Motorola M2000-355, we have the perfect LCD replacement for you. Why Choose Monitech for Fagor LCD Replacements? At Monitech, we understand the importance of having a reliable and efficient LCD display for your Fagor machine. That’s why we have dedicated ourselves to providing high-quality LCD replacements that meet the specific requirements of Fagor machines. Here are some reasons why you should choose Monitech for your Fagor LCD replacement: 1. Superior Quality Our LCD replacements are manufactured using the highest quality components to ensure superior performance and durability. We understand that Fagor machines are used in demanding industrial environments, and our LCD replacements are designed to withstand these conditions. 2. Easy Installation Our LCD upgrade kits are designed to be easily installed in Fagor machines. With detailed instructions and technical support, you can quickly and seamlessly upgrade your machine’s display without any hassle. 3. Compatibility Our LCD replacements are specifically designed to be compatible with Fagor machines. Whether you have a Fagor 8025, 8050, CNC 8030, 8050M Motion Master, 8035, or Motorola M2000-355, you can trust that our LCD replacements will work seamlessly with your machine. 4. Improved Performance By upgrading your Fagor machine with our LCD replacements, you can enjoy improved performance and functionality. Our LCD displays offer better clarity, resolution, and color reproduction, allowing you to have a better visual experience while operating your machine. Our Range of Fagor LCD Replacements At Monitech, we offer a wide range of LCD replacements for various Fagor machines. Here are some of our popular products: 1. Fagor 8025 LCD Upgrade Kit Upgrade your Fagor 8025 machine with our LCD upgrade kit. This kit includes a high-quality LCD display that is specifically designed to replace the original CRT display of the Fagor 8025. With improved clarity and resolution, you can enhance the performance of your Fagor 8025 machine. 2. Fagor LL-8050 LCD The Fagor LL-8050 LCD is a direct replacement for the original CRT display of the Fagor 8050 machine. With its high-quality LCD panel, this replacement offers better visibility and improved performance for your Fagor 8050 machine. 3. Fagor CNC 8030 LCD Upgrade Kit Upgrade your Fagor CNC 8030 machine with our LCD upgrade kit. This kit includes a high-quality LCD display that is specifically designed to replace the original CRT display of the Fagor CNC 8030. With improved clarity and resolution, you can enhance the performance of your Fagor CNC 8030 machine. 4. Fagor 8050M Motion Master Machine LCD Replace the original CRT display of your Fagor 8050M Motion Master Machine with our high-quality LCD replacement. This LCD display offers better visibility and improved performance, allowing you to operate your Fagor 8050M machine with ease. 5. Fagor LL-8035 LCD The Fagor LL-8035 LCD is a direct replacement for the original CRT display of the Fagor 8035 machine. With its high-quality LCD panel, this replacement offers better visibility and improved performance for your Fagor 8035 machine. 6. Motorola M2000-355 CRT to LCD Kit If you have a Motorola M2000-355 machine with a CRT display, our CRT to LCD kit is the perfect solution for you. Upgrade your machine with our high-quality LCD display and enjoy improved performance and reliability. Upgrade Your Fagor Machine with Monitech LCD Replacements Don’t let a faulty or outdated display hinder the performance of your Fagor machine. Upgrade it with a high-quality LCD replacement from Monitech. With our superior quality, easy installation, compatibility, and improved performance, you can trust that our LCD replacements will enhance the functionality and longevity of your Fagor machine. Visit our website today to explore our range of Fagor LCD replacements and find the perfect one for your machine.

Common Issues with CRT Displays on Legacy Machines Legacy CNC and PLC machines, such as those from Allen-Bradley, ProtoTrak, Mazak, Okuma, Heidenhain, Siemens, Fanuc, and Fagor, often come equipped with CRT displays. These CRT displays, while revolutionary at the time, have several issues: Dim or Flickering Screens: Over time, CRT displays can lose brightness and begin to flicker, making it difficult to read data accurately. Burn-In Problems: Static images displayed for long periods can cause permanent burn-in, affecting the display quality. High Power Consumption: CRT displays consume significantly more power compared to modern LCD displays, leading to higher operational costs. Bulky and Heavy: CRT monitors are large and heavy, taking up valuable space and making maintenance cumbersome. Solving CRT Display Issues Replacing the CRT display with an LCD display is the most effective solution. LCD displays are brighter, more energy-efficient, and free from burn-in issues. They also offer a more compact and lightweight alternative, enhancing the overall usability of the machine. Introducing Monitech’s LCD Display Replacements and CRT to LCD Upgrade Kits Monitech offers a comprehensive range of LCD display replacements and CRT to LCD upgrade kits tailored for various OEM machines. These upgrades are specifically designed to: Improve Display Quality: LCD displays provide clearer, brighter, and more consistent visuals, ensuring better readability and accuracy. Enhance Durability: LCD displays are more robust and have a longer lifespan compared to CRT displays. Reduce Energy Consumption: Upgrading to an LCD can significantly lower your machine’s power usage, reducing operational costs. Where to Buy Monitech’s LCD Display Replacements You can purchase Monitech’s LCD display replacements and upgrade kits directly from the Monitech website or through their distributor T2 Industrial. Case Study: Enhancing CNC Machine Efficiency A manufacturing company faced frequent downtimes due to the failing CRT display on their Heidenhain CNC machine. After switching to Monitech’s LCD display replacement, they noticed: Reduced Downtime: The new display eliminated flickering issues, ensuring continuous operation. Improved Operator Efficiency: Operators reported easier data reading and reduced eye strain. Cost Savings: Lower energy consumption and reduced maintenance needs led to significant cost savings over time. Frequently Asked Questions (FAQs) Q1: Are Monitech’s LCD replacements compatible with all legacy machines? A: Yes, Monitech offers LCD replacements compatible with a wide range of machines, including Allen-Bradley, ProtoTrak, Mazak, Okuma, Heidenhain, Siemens, Fanuc, and Fagor. Q2: How difficult is the installation process? A: The installation process is straightforward and can typically be completed without the need for extensive modifications to your existing setup. Q3: Do the LCD replacements come with a warranty? A: Yes, all Monitech LCD replacements come with a standard warranty for added peace of mind. Q4: Can I get custom solutions for specific needs? A: Absolutely. Monitech offers custom solutions to meet unique requirements. Conclusion Upgrading your legacy CNC and PLC machines from CRT to LCD displays is a smart investment that enhances performance, reduces costs, and prolongs the lifespan of your equipment. Monitech’s LCD display replacements offer a reliable and efficient solution for your display needs. Explore Monitech’s Repair Services and Custom Solutions In addition to LCD replacements, Monitech provides comprehensive repair services and custom solutions tailored to your specific requirements. Explore these options to ensure your machines run smoothly and efficiently. Embrace the future of machine displays with Monitech’s LCD display replacements and experience the difference in performance and reliability.

Addressing LCD Issues in Industrial Equipment Cana Datum Moulds Ltd, based in Etobicoke, Ontario, is renowned for manufacturing precision dies and tools for the nonferrous metal casting industry. Recently, they encountered a significant issue with their Toshiba BP-130.R22 Molding Machine – the original LCD displayed lines across the left side, impairing the machine’s functionality and efficiency. The Challenge The lines across the LCD of the Toshiba BP-130.R22 Machine posed significant challenges. Such visual disturbances can lead to misreads, operational delays, and even potential errors in production. Addressing this issue promptly was crucial to maintaining the integrity and performance of the molding machine. The Solution: Monitech’s LCD Panel Replacement To tackle this issue, Cana Datum Moulds Ltd contacted Monitech for a reliable and efficient solution. After assessing the problem, our team recommended and utilized the Monitech LCD Panel Replacement specifically designed for the NL6448AC33-10 NEC Panel used in the Toshiba Molding Machine. This replacement offered several key benefits: High Compatibility: The Monitech LCD Panel Replacement was designed to seamlessly integrate with the Toshiba BP-130.R22 Machine, ensuring minimal disruption during installation and optimal performance post-installation. Enhanced Durability: Built with industrial-grade materials, our LCD replacement ensures longevity and withstands the rigors of continuous use in a manufacturing environment. Improved Visual Clarity: The replacement panel provided crisp, clear visuals, eliminating the lines and ensuring accurate readings and operational efficiency. Implementation and Results The implementation process was smooth and efficient, carried out by our experienced technicians. The Toshiba BP-130.R22 Machine at Cana Datum Moulds Ltd was quickly back in operation with the new LCD panel. The replacement not only resolved the initial issue but also enhanced the overall visual clarity and reliability of the machine. Conclusion Monitech’s expertise in providing high-quality LCD replacements for industrial machinery ensures that manufacturers like Cana Datum Moulds Ltd can maintain their operations without prolonged downtime. By choosing Monitech, industries are guaranteed solutions that enhance machine performance and longevity. For more information on how Monitech can assist with your industrial display needs, visit Monitech.com. If you need a custom solution, you can contact us at Custom Solutions, and for repair services, please visit Repair Services.

Introduction to Centurion 5 Milltronics CNC The Centurion 5 Milltronics CNC machine has been a mainstay in industrial manufacturing for years. However, its CRT display technology is showing its age, leading to some challenges for businesses relying on these machines for precise operations. Challenges with Traditional CRT Displays Degradation and Obsolescence One of the main issues with CRT displays is that they degrade over time, resulting in a dimming screen and eventual failure. Finding replacement parts for these obsolete displays can be tough, making maintenance a hassle and costly. Limitations in Clarity and Resolution In comparison to modern LCD screens, CRT displays offer limited clarity and resolution. This impacts the visualization of control panels and operational data, potentially disrupting efficient workflow and creating room for errors. Benefits of Upgrading to Monitech’s LCD Kit Enhanced Visual Performance Monitech’s LCD upgrade kit provides a brighter, higher-resolution display, improving the visual performance of your Centurion 5 Milltronics CNC. This ensures clearer interface controls and data visualization, helping to maintain operational efficiency. Long-term Reliability and Support The LCD upgrade extends the display lifespan significantly, reducing the need for frequent replacements. Monitech also offers ongoing support for its products, ensuring long-term reliability and minimizing machine downtime. Installation Process of the LCD Upgrade Kit Monitech’s LCD upgrade kit includes everything needed for installation: a TFT-LCD screen, a cable kit, and mounting hardware. The installation process is straightforward and can be completed by following the included guide, making the upgrade accessible to a broader audience without specialized technical skills. Conclusion Upgrading your Centurion 5 Milltronics CNC with Monitech’s LCD kit offers a modern solution to replace obsolete CRT displays. The kit enhances display clarity, extends lifespan, and provides long-term support, ensuring efficient and reliable machine operation. This LCD upgrade is an ideal choice to revitalize legacy CNC machines, keeping your business productive and minimizing downtime.

Bosch CNC monitors are critical monitors for Trumpf Trumagraph machines. This product comes with an entire set of gains, while CRT technology, currently being used in these monitors, brings forth various challenges for an operator. They are very prone to degradation over time, like dim displays, ghosting, and also reduce the life of the monitor. They are also bulkier and hence more power-intensive, resulting in high operational and maintenance costs. An Effective Solution: Bosch Trumagraph LCD Upgrade Kit To address these challenges, an effective solution is to upgrade to LCD technology. Monitech offers an LCD upgrade kit for 12 inches, specially designed for the Bosch/Trumagraph monochrome CRT monitor. It is definitely a plug-and-play solution which requires no rewiring or reprogramming. It is accompanied with all the necessary cables and offers a longer life, over 50,000 hours. Offered for sale is a better-quality display and an energy-efficient LCD upgrade kit. In the CRT era, operators will be replacing the old technologies of CRT with the latest invented LCDs, wherein clear and brighter displays are obtained instead of putting up the problems like the dim display or ghosting, among others. The LCD technology requires less power, therefore, helping to reduce the operation cost and, in addition, is very friendly to the environment in a working place. Besides, this LCD upgrade kit was more durable compared to the previous version, unlike the installed monitor, which could serve longer periods without being frequently changed by the operator. Economical and Convenient Besides the above-mentioned technological advantages, the Bosch Trumagraph LCD upgrade kit further bears an economical value. The LCD upgrade kit is available at quite a good price in comparison to aging CRT technology. This is purposed to do away with frequent repairs or replacements and, in the long run, reduced maintenance costs. The reduced lead times for the orders also mean the operators get their LCD upgrade kits in time, hence experiencing minimal downtimes in their operations to maximize productivity. The Bosch Trumagraph LCD Upgrade Kit is readily available at the Monitech site for those who are out to upgrade. Monitech offers a guide and excellent customer support to help one in the process of installing their kit that facilitates transferring from CRT to LCD, making it easy. The instructions are clear and concise, including troubleshooting, therefore making the installation process of both physical and software installations a walk in the park for the operators. It will upgrade any CNC monitor to get a better performance and working life with a Bosch Trumagraph LCD Upgrade Kit. Its superior display quality, efficient in power use, and cost-effectiveness really make it a perfect solution for whoever would like to override the challenges brought about by CRT technology. Upgrade today to the LCD technology and experience the difference that it can present in your operations.

When it comes to technology, advancements are constantly being made to improve the user experience. One such advancement is the upgrade from CRT (Cathode Ray Tube) displays to LCD (Liquid Crystal Display) screens. Monitech, a leading provider of display solutions, offers the 14-inch LCD as a replacement for the Teleline KME 26814MA519 CRT. In this blog post, we will explore the benefits of this upgrade and provide a step-by-step guide on how to replace the CRT and upgrade it to an LCD display. The Advantages of LCD over CRT Before diving into the specifics of the 14-inch LCD, let’s first understand why upgrading from a CRT to an LCD display is beneficial. CRT displays have been the standard for many years, but they come with several drawbacks: Size and Weight: CRT displays are bulky and heavy, making them less portable and more challenging to handle. Power Consumption: CRT displays consume more power compared to LCD screens, leading to higher energy costs. Image Quality: LCD displays offer superior image quality, with sharper and more vibrant colors, higher resolution, and better contrast ratios. Eye Strain: CRT displays emit more flicker and glare, which can cause eye strain and fatigue over extended periods of use. Space Efficiency: LCD displays are thinner and take up less space, allowing for a more streamlined and organized workspace. The KME 26814MA519 LCD: A Superior Replacement The 14-inch LCD from Monitech is specifically designed as a replacement for the Teleline KME 26814MA519 CRT. This LCD display offers several advantages over its CRT counterpart: Compatibility: The 14-inch LCD is fully compatible with the Teleline KME 26814MA519 CRT, ensuring a seamless transition without the need for any additional modifications. Image Quality: With its LCD technology, the 14-inch LCD for KME 26814MA519 provides a clear and crisp display, enhancing the overall viewing experience. Energy Efficiency: LCD displays consume significantly less power than CRT screens, resulting in reduced energy costs and a more environmentally friendly solution. Space Saving: The slim design of the 14-inch LCD for KME 26814MA519 allows for more efficient use of space, freeing up valuable real estate on your desk or workstation. Longevity: LCD displays have a longer lifespan compared to CRT screens, reducing the need for frequent replacements and saving on maintenance costs. Step-by-Step Guide: Replacing the CRT and Upgrading to the 14-inch LCD for KME 26814MA519 Now that we understand the benefits of upgrading to the monitech’s 14-inch LCD for KME 26814MA519, let’s walk through the process of replacing the CRT and upgrading it to the LCD display: Preparation: Ensure that you have the necessary tools, including a screwdriver, to safely remove the CRT and install the LCD display. Power Off: Turn off the power to your device and unplug it from the electrical outlet. Remove the CRT: Carefully remove the CRT by unscrewing any fasteners or brackets holding it in place. Disconnect any cables connected to the CRT, taking note of their positions for reconnection later. Install the 14-inch LCD for KME 26814MA519: Align the LCD for KME 26814MA519 with the mounting holes and secure it in place using the provided screws. Connect the necessary cables to the corresponding ports on the LCD display. Power On: Plug in your device and turn on the power. The LCD for KME 26814MA519 should now be functioning as the new display. Adjust Settings (if necessary): Depending on your device, you may need to adjust the display settings to optimize the image quality of the KME 26814MA519 LCD. It is important to note that while the steps provided here are general guidelines, it is recommended to consult the user manual or seek professional assistance if you are unsure about any aspect of the replacement process. Conclusion Upgrading from a CRT to an LCD display offers numerous benefits, including improved image quality, energy efficiency, and space-saving advantages. The 14-inch LCD for KME 26814MA519 from Monitech serves as an excellent replacement for the Teleline KME 26814MA519 CRT, providing compatibility and superior performance. By following the step-by-step guide, you can easily replace the CRT and upgrade to the 14-inch LCD for KME 26814MA519, enhancing your overall viewing experience and productivity.

Industrial machines such as Okuma, Fanuc, Prototrak, Fagor, Cincinnati Milacron, and other OEMs have been using CRT displays for many years. However, with the advancement of technology, it is now possible to upgrade these old CRT displays to LCD screens. In this blog post, we will discuss the benefits of upgrading CRT displays to LCD and why it is a worthwhile investment for industrial machine owners. Improved Image Quality One of the main advantages of upgrading CRT displays to LCD is the improved image quality. CRT displays are known for their flickering screens and poor color reproduction. On the other hand, LCD screens offer a much clearer and sharper image with vibrant colors. This enhanced image quality can greatly improve the overall user experience and make it easier for operators to read and interpret the information displayed on the screen. Increased Reliability CRT displays are prone to failure due to their aging technology. They often suffer from issues such as screen burn-in, color fading, and image distortion. These problems can lead to downtime and costly repairs. Upgrading to LCD screens eliminates these reliability issues as LCD technology is more durable and less prone to failure. LCD screens also have a longer lifespan, reducing the need for frequent replacements. Compatibility with Modern Systems Another advantage of upgrading CRT displays to LCD is the compatibility with modern systems. Many industrial machines now use software-based control systems that require a digital display. CRT displays are analog and may not be compatible with these modern systems. By upgrading to LCD screens, machine owners can ensure that their machines are compatible with the latest software and can take advantage of new features and functionalities. Energy Efficiency CRT displays consume a significant amount of energy compared to LCD screens. Upgrading to LCD can result in energy savings, reducing the overall operating costs of the industrial machines. LCD screens are more energy-efficient as they do not require a high voltage power supply like CRT displays. This energy efficiency not only benefits the environment but also helps industrial machine owners save on electricity bills. Ease of Maintenance Maintaining CRT displays can be a challenging task. They require regular calibration and adjustments to ensure optimal performance. LCD screens, on the other hand, are relatively easy to maintain. They do not require any calibration and adjustments, resulting in less downtime and lower maintenance costs. Additionally, LCD screens are less susceptible to dust and dirt, making them easier to clean and keep in good condition. Cost-Effective Solution While upgrading CRT displays to LCD may require an initial investment, it is a cost-effective solution in the long run. The improved reliability and reduced maintenance requirements of LCD screens result in lower repair and replacement costs. Additionally, the energy efficiency of LCD screens leads to long-term cost savings on electricity bills. Considering the long lifespan of LCD screens, the investment in upgrading CRT displays to LCD is well worth it. Conclusion Upgrading CRT displays to LCD is a wise decision for industrial machine owners. The benefits of improved image quality, increased reliability, compatibility with modern systems, energy efficiency, ease of maintenance, and cost-effectiveness make it a worthwhile investment. If you own an Okuma, Fanuc, Prototrak, Fagor, Cincinnati Milacron, or any other OEM industrial machine with an old CRT display, consider upgrading to an LCD screen to enhance the performance and usability of your machine.

CNC Monitor Replacements by Monitech When it comes to CNC machines, having a reliable and high-quality monitor is essential for smooth operation and accurate results. However, over time, monitors can become outdated or malfunction, causing disruptions in productivity and potentially leading to costly errors. That’s where Monitech comes in. All about CNC LCD Upgrade Kits Monitech specializes in providing top-of-the-line CNC monitor replacements through their extensive range of LCD upgrade kits. These kits are designed to replace outdated CRT monitors with modern LCD screens, offering numerous benefits such as improved image quality, reduced power consumption, and increased durability. Wide Range of CNC LCD Upgrade Kits Monitech offers a wide range of CNC LCD upgrade kits, catering to various CNC machine models and brands. Some of the popular options include: Allen-Bradley 8400 CNC LCD Upgrade Kit: This kit is specifically designed to replace the outdated monitors in Allen-Bradley 8400 CNC machines. With its high-resolution LCD screen, operators can enjoy clear and crisp visuals, enhancing their overall experience and productivity. Fagor 8050 CNC LCD Upgrade Kit: The Fagor 8050 CNC LCD upgrade kit is a perfect solution for those looking to replace the CRT monitors in their Fagor 8050 CNC machines. The kit offers improved color reproduction and a wider viewing angle, ensuring accurate and precise monitoring. Siemens CNC Cincinnati Milacron Acramatic 2100 LCD Upgrade Kit: Monitech’s LCD upgrade kit for Siemens CNC Cincinnati Milacron Acramatic 2100 machines is designed to provide a seamless transition from CRT to LCD. The kit offers enhanced clarity and readability, making it easier for operators to monitor their CNC processes. Polars EMC Cutter CNC LCD Upgrade Kit: With the Polars EMC Cutter CNC LCD upgrade kit, operators can replace the outdated CRT monitors in their Polars EMC Cutter machines. The kit features a high-quality LCD screen with excellent color reproduction, ensuring accurate and detailed monitoring. Intecolor 3102 CNC LCD Upgrade Kit: The Intecolor 3102 CNC LCD upgrade kit is a reliable solution for replacing CRT monitors in Intecolor 3102 CNC machines. The kit offers improved contrast and brightness, allowing operators to easily view and analyze their CNC processes. Allen-Bradley 8520 Series 9 CNC LCD Upgrade Kit: Monitech’s LCD upgrade kit for Allen-Bradley 8520 Series 9 CNC machines provides a seamless transition from CRT to LCD. The kit offers excellent image quality and a wide viewing angle, ensuring optimal monitoring and control. Anilam 3300 CNC LCD Upgrade Kit: The Anilam 3300 CNC LCD upgrade kit is designed to replace the outdated monitors in Anilam 3300 CNC machines. With its high-resolution LCD screen, operators can enjoy clear and detailed visuals, enhancing their overall productivity. Mitsubishi Meldas 300 CNC LCD Upgrade Kit: Monitech’s LCD upgrade kit for Mitsubishi Meldas 300 CNC machines is a reliable solution for replacing CRT monitors. The kit offers improved color accuracy and a wider viewing angle, ensuring operators can monitor their CNC processes with ease. These are just a few examples of the CNC LCD upgrade kits offered by Monitech. They have a comprehensive range of kits available for various CNC machine models, ensuring that operators can find the perfect replacement for their specific needs. With Monitech’s CNC monitor replacements, operators can experience improved productivity, reduced downtime, and enhanced visualization of their CNC processes. The LCD upgrade kits are easy to install, ensuring a hassle-free transition from CRT to LCD monitors. Why Choose Monitech? There are several reasons why Monitech stands out as a reliable provider of CNC monitor replacements: Expertise: Monitech has years of experience in the industry and understands the unique requirements of CNC machines. They have a team of experts who can guide customers in choosing the right LCD upgrade kit for their specific needs. Quality: Monitech is committed to delivering top-quality products. Their CNC LCD upgrade kits are manufactured using high-grade components to ensure durability and long-lasting performance. Compatibility: Monitech’s LCD upgrade kits are designed to be compatible with a wide range of CNC machine models and brands. This ensures that operators can find the right replacement for their specific machine without any compatibility issues. Customer Support: Monitech provides excellent customer support, assisting customers throughout the entire process, from selecting the right LCD upgrade kit to installation and troubleshooting. Cost-Effective: Investing in Monitech’s CNC monitor replacements is a cost-effective solution compared to purchasing a new CNC machine. The LCD upgrade kits offer improved performance and longevity, extending the lifespan of existing CNC machines. Overall, Monitech’s CNC monitor replacements offer a reliable and efficient solution for upgrading outdated CRT monitors to modern LCD screens. With their wide range of CNC LCD upgrade kits and commitment to quality, Monitech is a trusted choice for CNC machine operators looking to enhance their productivity and accuracy.

In industrial automation, the names Cutler-Hammer, Modicon, and Eaton stand out for their historical significance and contributions to electrical control and power management. These systems, developed over decades, have been central to advancements in industrial processes. However, as technology progresses, maintaining and upgrading these legacy systems poses a unique challenge. The Legacy Challenge Cutler-Hammer and Modicon, now under Eaton’s umbrella, represent a legacy of industrial automation that spans over a century. The acquisition of Cutler-Hammer by Eaton in 1978 marked a strategic move into the electronic components and factory automation sectors, highlighting the importance of innovation in responding to market needs. Finding suitable replacements for parts of these aging systems is increasingly difficult due to their specialized nature and the obsolescence of components. This challenge is compounded by the potential operational disruptions that come with system overhauls, making it crucial to find solutions that offer minimal downtime. Monitech’s Role in Modernization Monitech has carved a niche for itself by addressing the specific needs of updating legacy systems. Their LCD upgrade kits for Panelmate Modicon systems exemplify this approach, offering a simple yet effective solution to replace outdated CRT displays with modern LCDs. This upgrade significantly improves display quality and aligns with the shift towards more energy-efficient and environmentally friendly technology. By providing a bridge between old and new technologies, Monitech enables companies to extend the life of their existing systems without the extensive costs and disruptions of full replacements. This practical approach to modernization is especially valuable in industries where reliability and uptime are critical. The Bottom Line The transition from CRT to LCD displays, facilitated by Monitech’s upgrade kits, is a clear example of how industries can evolve without leaving behind the valuable infrastructure that has served them well for years. It’s a testament to the importance of innovation that respects the past while paving the way for the future. Monitech’s solutions offer a straightforward, cost-effective path to modernizing industrial automation systems, ensuring that the legacies of Cutler-Hammer, Modicon, and Eaton continue to support the industries they serve. This approach not only enhances operational efficiency but also contributes to sustainability goals by reducing waste and energy consumption. Need Help with Old Machines? Contact Our Experts! Struggling with outdated machinery display? Don’t worry, our team of experts is here to assist you. Feel free to contact us for any guidance on HMI replacements or other machinery-related issues. We’re ready to provide the support you need. Stay on top of the latest developments by following us on Facebook, Twitter, LinkedIn, and YouTube. We regularly post a wealth of information, from the latest news to practical tips in the world of industrial displays. Our product catalog offers replacement parts for various brands including Allen-Bradley, Siemens, Anilam, Dynapro, Fanuc, and more. Discover the solutions we offer by exploring our product catalog.

The Mazak 8DSP40, known for its robustness and reliability, has been a key player thanks to its 14-inch color CRT display. However, the march of technology has made the CRT’s limitations increasingly clear. They’re bulky, power-hungry, and don’t offer the clarity of modern displays. Furthermore, finding replacement parts for obsolete technology has become a growing challenge. Monitech has stepped in with a practical solution to this dilemma. They’ve developed an LCD upgrade kit tailored for the Mazak 8DSP40 and similar models. This kit isn’t just about embracing new technology—it’s about making older systems more efficient and reliable. The Drive for Upgrades For decades, displays like the 8DSP40 have been at the heart of CNC operations. But as CRT technology fades into history, maintaining these systems has become both complicated and costly. This shift isn’t just about moving to newer technology; it’s about keeping vital machinery in peak condition without breaking the bank. Introducing Monitech’s LCD Kit Monitech’s solution is a direct response to the need for an accessible, efficient upgrade path. Their LCD upgrade kit for the Mazak 8DSP40 transforms outdated CRT monitors with crisp, energy-efficient LCD displays. Engineered for easy installation, the kit ensures compatibility by mirroring the original monitor’s specifications, minimizing machine downtime. Explore the specifics of this upgrade on Monitech’s product page: Monitech’s 8DSP40 LCD Kit. Why Upgrade? Switching to LCD technology brings clear advantages. Beyond the obvious improvements in display quality and energy consumption, LCDs are lighter and offer greater reliability. This upgrade is an investment in the machine’s future, reducing the need for maintenance and ensuring operational efficiency. Final Thoughts Monitech’s LCD upgrade kit represents a smart approach to modernizing CNC machinery. By providing a high-quality, compatible display solution, they ensure that older machines like the Mazak 8DSP40 can continue to contribute to productivity with renewed efficiency. This move towards modernization isn’t just about keeping up with technology—it’s about making smart, sustainable choices for the future of manufacturing. Need Help with Old Machines? Contact Our Experts! Struggling with outdated machinery display? Don’t worry, our team of experts is here to assist you. Feel free to contact us for any guidance on HMI replacements or other machinery-related issues. We’re ready to provide the support you need. Stay on top of the latest developments by following us on Facebook, Twitter, LinkedIn, and YouTube. We regularly post a wealth of information, from the latest news to practical tips in the world of industrial displays. Our product catalog offers replacement parts for various brands including Allen-Bradley, Siemens, Anilam, Dynapro, Fanuc, and more. Discover the solutions we offer by exploring our product catalog.