Overview

Monitech successfully transformed the display technology at Bend All Automotive Inc. by upgrading their Matsushita TR-9DD1B old monitor from a CRT to a modern LCD kit. This case study explores the challenges faced with the old CRT monitor and the benefits realized through the upgrade.

Challenge

Bend All Automotive Inc. was relying on an outdated Matsushita TR-9DD1B monitor, a common issue in many industrial settings. The CRT (Cathode Ray Tube) technology, once a standard, was proving inefficient and inadequate for modern demands. Common issues with such old CRT monitors include:

Solution

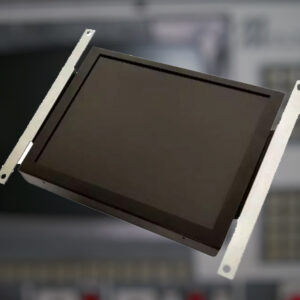

Monitech provided a state-of-the-art solution – the ML080QT9DDS, an 8.0″ LCD upgrade kit designed specifically for the Matsushita TR-9DD1B with a 9″ CRT. This kit is also compatible with other models like MDT-941 and TR-90B1. The LCD upgrade offers:

Implementation

The upgrade process was smooth and efficient. Monitech’s team ensured compatibility and seamless integration of the new LCD kit with the existing system at Bend All Automotive Inc. Special attention was given to ensure no disruption to the daily operations.

Outcome

Post-installation, Bend All Automotive Inc. experienced immediate improvements:

NEED TO REPLACE YOUR DISPLAY?

We have a wide-range of industrial display replacement that fits on your industrial machine.