A trendsetter in CNC machines that proudly display and work with special emphasis on moving from traditional CRT screens to smart and effective LCD displays. The Fagor 8020 and 8025 CNC controllers that came with it came with a CRT monitor. These were great but rugged performers as the standard in professional milling.

Effective in their time, this moment they have been cut into small figures in sections like clarity and energy efficiency. This is something I hope to be able to get to the bottom of and figure out why this is such a game-changer of a technology upgrade for LCDs.

The Fagor 8020 is out of the 800 series, which is standard for fast and precise machining. However, its older CRT technology can bring about problems such as loss of machine parameters when the battery dies.

This often results in error codes that interrupt production, preventing machines from performing at their best. Proper maintenance of such systems and making sure that the backup of essential parameters is held would be the most essential. But perhaps most important in all of these upgrades is moving to a more contemporary display technology, which can significantly boost both the performance and reliability of the machine.

In other words, since LCDs offer sharper images, it will be easier to monitor and adjust machine operations with more clarity.

More reliability: LCDs do away with common problems of a CRT, such as picture burn-in, and also offer a longer service life, usually over 50,000 hours.

Energy Efficiency: LCDs are much more power-efficient, which translates to cost savings and a smaller carbon footprint.

Lower Maintenance: With fewer issues to fix, LCDs reduce both downtime and the expense of repairs. Monitech’s LCD Upgrade Kits

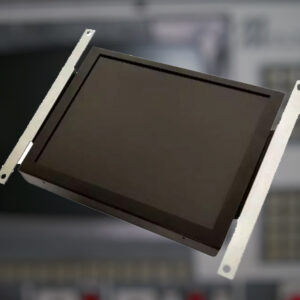

At Monitech, we have our LCD upgrade kits perfected. Compatible with Fagor 8020/8025 controllers, these kits include new LCD displays, all necessary cables, and mounting brackets to make that change from old to new as easy as possible. This is not only designed to improve the looks but also it upgrades your equipment to a more matching level with modern technology standards.

Broader Impact and Availability

Broader Impact and AvailabilityOur LCD upgrade kits are designed to be compatible with a broad range of Fagor controllers, including both the Fagor 8020 and 8025 models. These kits support various display sizes, extending from the more common 15-inch screens down to the 9-inch screens used in the 8025 model. This versatility allows you to modernize even the oldest CNC machinery to meet current operational demands without the significant expense of purchasing new equipment.

Deciding on a replacement with an LCD display for your Fagor 8020/8025 CNC controllers exceeds making just an upgrade. It is a decision that will completely modify the running of your CNC machine to be more efficient and accurate. At Monitech, we are able to help guide you in this upgrade process at every stage, from picking out the right kit to installation. More details on how to retrofit your CNC machine with a modern display can be found in our article Retrofit of the Monitech Fagor 8025 LCD Upgrade Kit. Take the first steps toward the future of CNC Machining with Monitech’s groundbreaking solutions, boosting your operational excellence to the next level!

NEED TO REPLACE YOUR DISPLAY?

We have a wide-range of industrial display replacement that fits on your industrial machine.