In industrial automation, particularly with CNC machines, display units are a critical component for machine operators. The displays provide a direct interface with the machinery, allowing for monitoring and control of the manufacturing process. FANUC CNC machines have historically utilized CRT (Cathode Ray Tube) monitors, specifically the 14″ Fanuc A61L-0001-0074 CRT, compatible with Fanuc 15T, Fanuc 10, and Fanuc 10TE-F Control systems, often the Matsushita TX1404-AB CRT. This monitor is also found in Hitachi Seike HT-25S machines equipped with the Fanuc 10TE-F Controller. However, these CRT displays are now facing obsolescence and reliability issues due to their age.

This article will address the technical difficulties that users of these FANUC CNC machines commonly encounter with old CRT monitors. We will outline the problems that can disrupt production and the maintenance challenges that often accompany these outdated components.

Limited Resolution: Fanuc CRT displays, while reliable, have limitations when it comes to resolution. This can hinder the clarity of visuals, especially in applications that require precision and detail.

Weight and Bulk: Fanuc CRT displays, although robust, tend to be bulky and heavy. This can pose challenges during installation, maintenance, and relocation, potentially causing ergonomic concerns for operators.

Energy Inefficiency: Fanuc CRT displays are known for their higher power consumption compared to modern flat-panel displays. This not only increases operational costs but also contradicts energy-saving goals.

Heat Generation: CRT displays generate significant heat during operation, which can be problematic in enclosed industrial environments. Excess heat can lead to discomfort for operators and potential overheating issues.

Limited Lifespan: Fanuc CRT displays have a finite lifespan, and finding replacement parts can be increasingly difficult as manufacturers discontinue production. This results in extended downtime and higher maintenance expenses.

Image Distortion: Over time, Fanuc CRT displays may develop image distortion issues, such as screen burn-in or color imbalances. These problems can compromise the accuracy of visual data.

Compatibility Challenges: Integrating Fanuc CRT displays with modern industrial machines and control systems can be cumbersome due to differences in display technology. This can result in additional costs and complexities.

Regulatory Compliance: In some industries, specific regulations govern display technology standards. Outdated CRT displays may not meet these requirements, potentially leading to compliance issues.

Reduced Productivity: Fanuc CRT displays’ limitations can impact operator productivity, especially in applications that require high-resolution visuals or rapid data processing.

Maintenance Complexity: As CRT technology becomes less common, finding qualified technicians who can service and repair these displays can become increasingly challenging and costly.

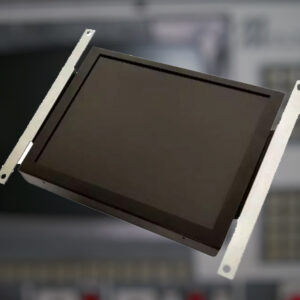

To address the challenges associated with Fanuc CRT displays, Monitech offers a tailored solution: Fanuc LCD Replacement Kits. These kits are engineered to provide Fanuc machines with a seamless transition to modern LCD technology. Here’s why they are the ideal choice:

Improved Resolution: Monitech’s LCD replacement kits offer significantly higher resolution displays, ensuring superior image clarity and precision. This is particularly beneficial for Fanuc applications that require fine details.

Reduced Weight and Bulk: Our LCD replacement kits are designed to be slim and lightweight, simplifying installation, maintenance, and relocation. Say goodbye to the ergonomic challenges of heavy CRT displays.

Energy Efficiency: Monitech’s LCD displays are energy-efficient, resulting in lower operating costs and alignment with sustainability objectives. They consume less power while delivering exceptional performance.

Heat Management: Unlike CRT displays, our LCD replacements generate minimal heat, making them ideal for enclosed industrial environments. Operators can work comfortably without concerns about overheating.

Extended Lifespan: Monitech’s LCD displays are built to last, reducing the need for frequent replacements and minimizing maintenance costs.

Image Quality: Our LCD replacement kits provide crystal-clear images without the distortion issues that plague CRT displays over time. Operators can trust the accuracy of their visual data.

Compatibility: Monitech’s LCD replacement kits are designed with Fanuc compatibility in mind. They seamlessly integrate with Fanuc machines and control systems, simplifying the transition process.

Regulatory Compliance: Our LCD replacement solutions meet the stringent requirements of various industrial sectors, ensuring businesses stay compliant with industry standards.

Enhanced Productivity: By upgrading to Monitech’s LCD solution, businesses can significantly improve operator productivity. High-resolution visuals, rapid data processing, and reduced downtime all contribute to enhanced efficiency.

Easy Maintenance: Monitech’s LCD replacement kits are easy to maintain, reducing the burden of finding qualified technicians for servicing. This simplifies the maintenance process and minimizes associated costs.

To illustrate the tangible impact of Monitech’s Fanuc LCD replacement solutions, let’s explore real-world examples:

Case Study: Precision Manufacturing

A precision manufacturing company was facing significant challenges with their outdated CRT displays in their CNC machines, specifically the Fanuc 15T model, equipped with the Matsushita TX1404-AB CRT.

The primary problem was the limited resolution of these displays, which hindered the precision and accuracy required for their intricate work. The weight of the CRT added to their woes, leading to ergonomic concerns for operators who had to interact with this heavy display regularly.

In search of a solution, the company turned to Monitech’s advanced LCD replacement kits, including the 14-inch Fanuc A61L-0001-0074 CRT replacement kit. This kit was not only compatible with their existing Fanuc 15T machine but also promised a significant enhancement in display performance.

After the installation of Monitech’s LCD replacement kit, the company experienced a remarkable transformation in their operations. The higher resolution display of the Fanuc A61L-0001-0074 replacement kit allowed for precise and accurate work, effectively reducing errors and rework. Additionally, the reduced weight of the LCD display eliminated ergonomic concerns and operator discomfort, contributing to improved efficiency.

The benefits extended to their Fanuc 15T machine, as the LCD replacement not only improved the visual clarity but also extended the lifespan of the display, resulting in fewer replacements and lower maintenance expenses.

In essence, Monitech’s Fanuc A61L-0001-0074 CRT replacement kit proved to be the ideal solution for precision manufacturing when it came to upgrading their Fanuc 15T machine. It addressed their specific display challenges and significantly enhanced their overall productivity and efficiency.

Now that you understand the benefits of upgrading to Monitech’s Fanuc LCD replacement kits, here’s a straightforward guide on how to make the transition:

Assessment: Begin by assessing your current Fanuc CRT displays and identifying specific models and compatibility requirements.

Consultation: Contact Monitech for a consultation. Our experts can help you determine the right LCD replacement kit for your Fanuc machines.

Installation: Once you’ve selected the appropriate kit, follow the provided installation instructions. In most cases, the process is straightforward and can be completed with minimal downtime.

Our Installation Video for the 14-inch Fanuc LCD Monitor Upgrade:

Integration: Our LCD replacements are designed for seamless integration with your existing Fanuc machines and control systems. Ensure that they work smoothly with your equipment.

Maintenance: Enjoy the reduced maintenance needs of your new LCD displays. Regularly cleaning the screens and keeping them free from dust and debris will help maintain their performance.

In conclusion, Fanuc CRT displays have served as stalwarts in industrial settings, but they come with their share of challenges. The time has come to embrace the future by upgrading to Monitech’s Fanuc LCD replacement solutions. This transition is akin to moving from outdated technology to a cutting-edge display system that significantly enhances operational efficiency.

At Monitech, we’re here to help you find the best solution for your needs – contact us today to learn more about Monitech’s LCD Upgrade Kits and how they can benefit your industrial processes.

Do you have problems with old machines that you can’t find a solution to? Contact our experts! Our team not only offers replacement parts but also provides industrial display repair services. And don’t forget to stay tuned to our pages on Facebook, Twitter, and YouTube for the latest news.

If you need guidance or any help in replacing or repairing your HMI, our team of experts is available to assist you. Simply give us a call or send us an email.

We offer multiple replacement parts for units from brands like Allen-Bradley, Siemens, Mazak, Okuma, and Nematron, among others. Check out our product catalog for more information.

https://monitech.com/products/lcd-upgrade-fanuc-0074-crt/

Phone: 877-493-6105

Local: 519-725-2222

Email: sales@monitech.com

Office in Canada: 20 Howard Place, Kitchener, Ontario, Canada, N2K 2Z4

Office in USA: 8955 US-301 Parrish, FL. 34219 – USA

NEED TO REPLACE YOUR DISPLAY?

We have a wide-range of industrial display replacement that fits on your industrial machine.