Introduction: Navigating the complexities of CNC system troubleshooting can be a daunting task, especially when dealing with older models like the Fagor 8025. In this blog post, we explore a real-life scenario shared in a forum discussion, highlighting the challenges and solutions involved in fixing a malfunctioning Fagor 8025 CNC system used to run a Hardinge lathe.

The Initial Problem: Our journey begins with a user experiencing a sudden freeze on their CNC system’s screen during a spindle warm-up. Attempts to restart did not resolve the issue, leaving the user with a non-responsive screen. Initial checks like inspecting the fuses didn’t yield any clues, leading the user to seek advice from the community.

Community Insights and Suggestions: The CNC community offered valuable insights, pointing out that a flat battery typically doesn’t prevent control boot-up but can affect display functionality. Several potential issues were identified:

These insights were accompanied by a cautionary note: Fagor no longer supports the 8025 control, and finding replacement parts could be costly. An alternative proposed was upgrading to the Fagor 8037 control, a newer but expensive option (around $6000).

Diagnostic Steps and User Feedback: To narrow down the problem, the user was advised to perform specific checks, including listening for operational sounds, checking for error codes, and testing key strokes for any machine response. The user’s findings pointed towards a possible video or voltage issue – the machine made electrical sounds and responded to key inputs, but the screen remained blank, and there was no axis movement.

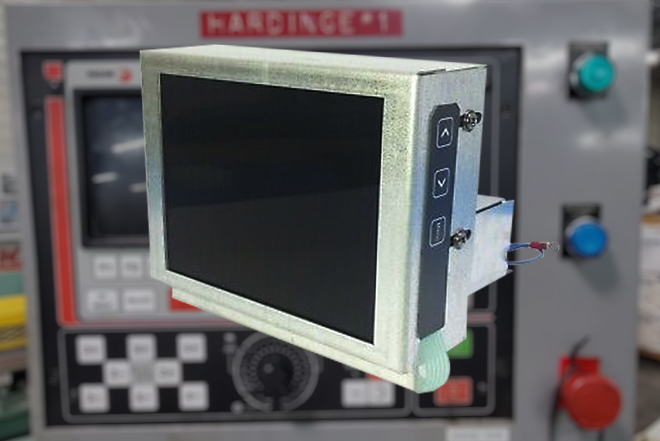

Resolution and Affordable Solution: After further investigation, it was revealed that the main motherboard had failed. A replacement was sourced, and the system was reconfigured. However, the user also considered upgrading to a newer LCD system. While the Fagor 8037 was out of their budget, they found an affordable and compatible LCD replacement from Monitech, priced around $1400. This LCD upgrade kit offers a cost-effective solution for those not ready for a full system overhaul.

Monitech’s LCD Upgrade Kit: For users facing similar display issues with the Fagor 8025, Monitech’s LCD Upgrade Kit presents a practical solution. More details about this product can be found on their product page. This kit not only enhances the display but also extends the life of the CNC system at a fraction of the cost of a complete control upgrade.

Conclusion: This case study underscores the importance of community support and shared knowledge in troubleshooting CNC systems. It also highlights how innovative solutions like Monitech’s LCD Upgrade Kit can provide cost-effective alternatives to expensive upgrades or replacements.

Need Help with Old Machines? Contact Our Experts!

Struggling with outdated machinery display? Don’t worry, our team of experts is here to assist you. For any guidance on HMI replacements or other machinery-related issues, feel free to give us a call or send us an email. We’re ready to provide the support you need.

Stay on top of the latest developments by following us on Facebook, Twitter, LinkedIn, and YouTube. We regularly post a wealth of information, from the latest news to practical tips in the world of industrial displays.

Our product catalog offers a wide array of replacement parts for various brands including Allen-Bradley, Siemens, Anilam, Dynapro, Fanuc, and more. Discover the solutions we offer by exploring our product catalog.

Stay Informed:

For more insights, stories, and tips on industrial machineries, keep following our blog. Our posts are packed with valuable information that could be the solution you’re looking for. Your next breakthrough in handling industrial display issues on your machinery might just be a blog post away!

At Monitech, we are dedicated to helping you navigate the complexities of industrial machinery with ease. Reach out to us today for expert advice and solutions tailored to your needs.

NEED TO REPLACE YOUR DISPLAY?

We have a wide-range of industrial display replacement that fits on your industrial machine.