Overview:

In the hot summer of 2023, a Michigan-based automotive parts manufacturer encountered a crucial challenge. Their production efficiency was significantly hindered by the frequent malfunctioning of their 2711P PanelView Plus 7 touchscreens, a vital component of their production line. The extreme heat led to regular unresponsiveness and misalignment of the screens, causing not just operational delays but also impacting the overall workflow and productivity. This issue necessitated an urgent solution to maintain the company’s manufacturing output and quality standards.

Case Study:

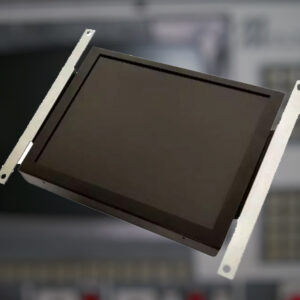

The engineering team, observing the recurring issues during the peak of Michigan’s summer, initiated an in-depth analysis. They identified that the touchscreens’ failures were primarily due to the intense heat, which affected their performance and calibration. After researching potential solutions, they decided to trial Monitech’s MF1900PPT7-22 touchscreen. The trial period revealed significant improvements in durability and functionality under extreme conditions. Impressed by these results, the team unanimously decided to place a bulk order for these screens from Monitech.com, aiming to replace the existing, less durable screens.

Solution:

The implementation of Monitech’s touchscreens led to a substantial decrease in operational issues. The company documented a 30% reduction in downtime, a figure that significantly boosted its production efficiency. “The impact of Monitech screens was beyond our expectations,” remarked the lead engineer. These screens, which were more suited to withstand harsh environmental conditions, also enhanced the user experience. The decision to keep a bulk stock became a critical component of their maintenance strategy, ensuring a swift response to any future touchscreen issues.

Conclusion:

Adopting Monitech’s MF1900PPT7-22 touchscreens marked a significant turning point for the company. This strategic decision not only addressed their immediate technological challenges but also set a new precedent in their approach to operational efficiency. The company’s ability to adapt and invest in a reliable and efficient solution has since been recognized as an exemplary model in the automotive manufacturing industry, especially in managing environmental and technological challenges.

NEED TO REPLACE YOUR DISPLAY?

We have a wide-range of industrial display replacement that fits on your industrial machine.