Industrial machines, such as Allen Bradley PanelViews, are the backbone of many manufacturing and processing industries. A key component of these machines is the touchscreen display, which allows operators to control and monitor the machine’s functions seamlessly. However, like all technological components, touchscreens can wear out or get damaged over time. Knowing when to replace the touchscreen can save you from unexpected downtime and maintain operational efficiency. Here are some typical signs to watch out for, along with best practices for maintenance and common mistakes to avoid.

While regular maintenance can be carried out by the users, professional servicing is recommended periodically. The frequency of professional servicing may vary based on usage intensity, environmental conditions, and manufacturer recommendations. Services typically include:

In addition to the valuable information provided, we understand the importance of having practical, easy-to-use tools at your disposal. That’s why we’ve compiled all the crucial points mentioned above into a user-friendly, downloadable checklist. This comprehensive checklist serves as a convenient reference to help you assess the condition of your industrial machine’s touchscreen and determine if a replacement is necessary.

Simply click the link above to download your copy. This checklist is designed to be printed and used as a physical reference during your touchscreen evaluations. Keep it accessible in your workspace to ensure consistent maintenance checks and to help identify any potential issues early on.

Remember, a proactive approach to maintaining your industrial touchscreen can save you time and resources in the long run. By regularly using this checklist, you’re taking an important step in preserving the operational integrity and longevity of your industrial machines.

Remember, a well-maintained touchscreen not only extends the life of your industrial machine but also ensures safety and efficiency in your operations. Paying attention to the signs of wear and damage, practicing regular maintenance, and avoiding common mistakes can go a long way in maintaining the optimal performance of your industrial machine’s touchscreen.

Struggling with outdated machinery display? Don’t worry, our team of experts is here to assist you. For any guidance on HMI replacements or other machinery-related issues, feel free to give us a call or send us an email. We’re ready to provide the support you need.

Stay on top of the latest developments by following us on Facebook, Twitter, LinkedIn, and YouTube. We regularly post a wealth of information, from the latest news to practical tips in the world of industrial displays.

Our product catalog offers a wide array of replacement parts for various brands including Allen-Bradley, Siemens, Anilam, Dynapro, Fanuc, and more. Discover the solutions we offer by exploring our product catalog.

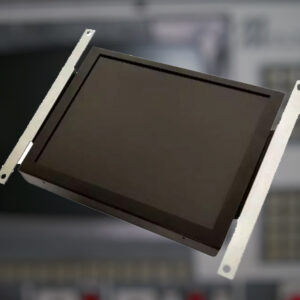

NEED TO REPLACE YOUR DISPLAY?

We have a wide-range of industrial display replacement that fits on your industrial machine.